Advantages of Stamping for Optical Module Housing

1. Cost-effective Production

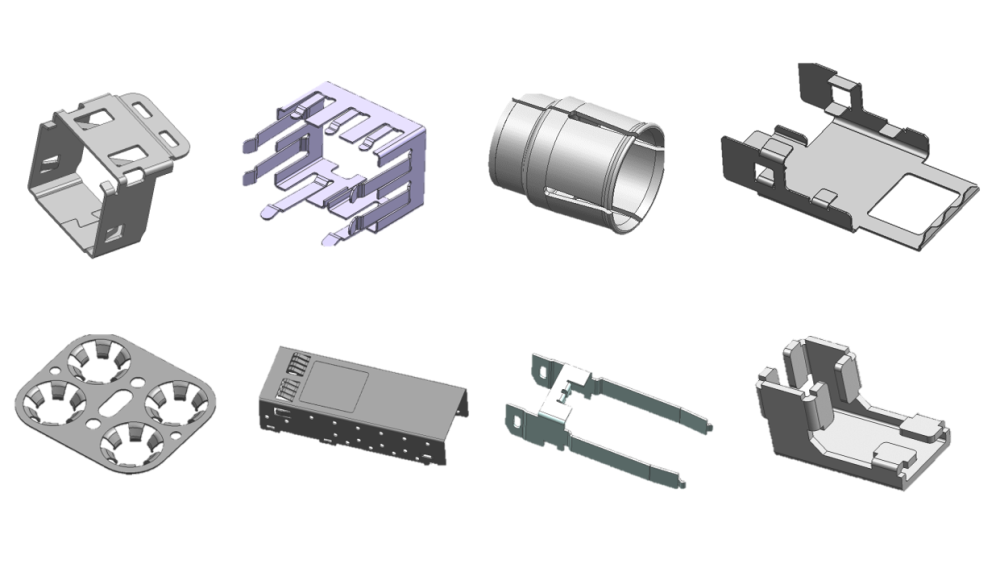

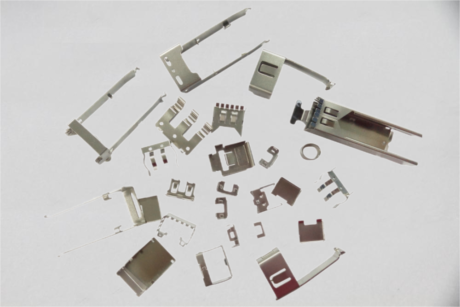

Stamping Component is a sheet metal stamping.Stamping process is a metal processing method, it is built on the basis of plastic deformation of metal.It has the characteristics of high production efficiency, easy operation, and easy mechanization and automation.Stamping is a highly efficient and cost-effective manufacturing process for optical module housing. By utilizing custom-designed dies and presses, stamping allows for the mass production of complex shapes and designs with minimal material waste. This results in lower production costs compared to other manufacturing methods, such as machining or casting.

2. High Precision and Consistency

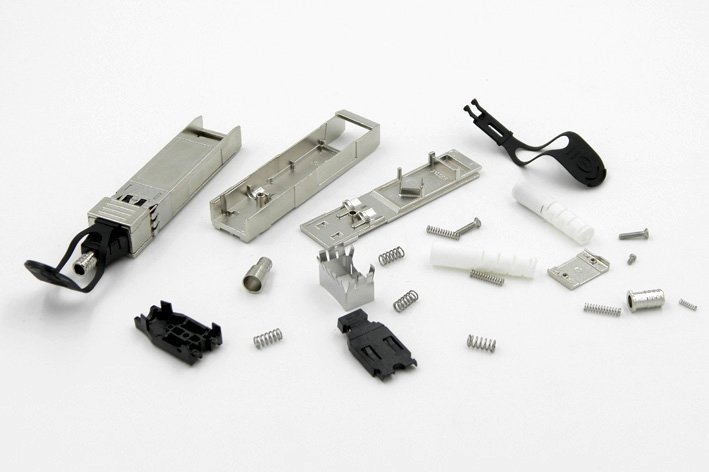

Stamping offers exceptional precision and consistency in producing optical module housings. The use of precision dies ensures that each stamped housing is identical in shape and size, leading to better compatibility and ease of assembly. This level of precision is crucial for optical modules, as any variations in the housing can negatively impact the performance and reliability of the module.

3. Enhanced Durability and Strength

Stamping allows for the creation of optical module housings with superior durability and strength. The process involves shaping metal sheets through high-pressure presses, resulting in housings that can withstand harsh environmental conditions and mechanical stress. Stamped housings are known for their rigidity and resistance to deformation, ensuring the long-term reliability of the optical module.

In conclusion, stamping offers several advantages for the stamping component of optical module housings. Its cost-effectiveness, high precision, and enhanced durability make it a preferred manufacturing method in the optical industry. By choosing stamping, manufacturers can ensure the quality and performance of their optical modules while optimizing production costs.

Stamping Component is a sheet metal stamping.Materials such as cold-rolled steel (CRS), hot-rolled steel, stainless steel, galvanized, brass, aluminum, and beryllium copper among others. We offer complete secondary operations including powder coating, painting, anodizing, silk screening, and pad printing. Assembly services are also available.

We sincerely hope to cooperate with you to build our future together!