Introduce the Optical Transceiver Housing

Optical transceiver housing is crucial for ensuring the performance and reliability of these components in various network applications. They are typically classified by the materials used, including metal, plastic, and hybrid versions, each offering distinct advantages and disadvantages.

Metal housings, often made of aluminum or other lightweight alloys, are known for their excellent durability and robust thermal management. These housings efficiently dissipate heat, reducing the risk of thermal damage to internal components. Additionally, metal housings provide superior electromagnetic interference (EMI) shielding, which is essential in environments with high electromagnetic noise. However, the downside is their higher cost compared to plastic alternatives.

Plastic housings, on the other hand, are more cost-effective and lighter in weight. Advances in engineering polymers have made plastic casings more durable and resistant to environmental factors. Despite their affordability, plastic housings typically offer less efficient thermal management and EMI shielding compared to metal housings. This makes them more suitable for less demanding applications.

Types

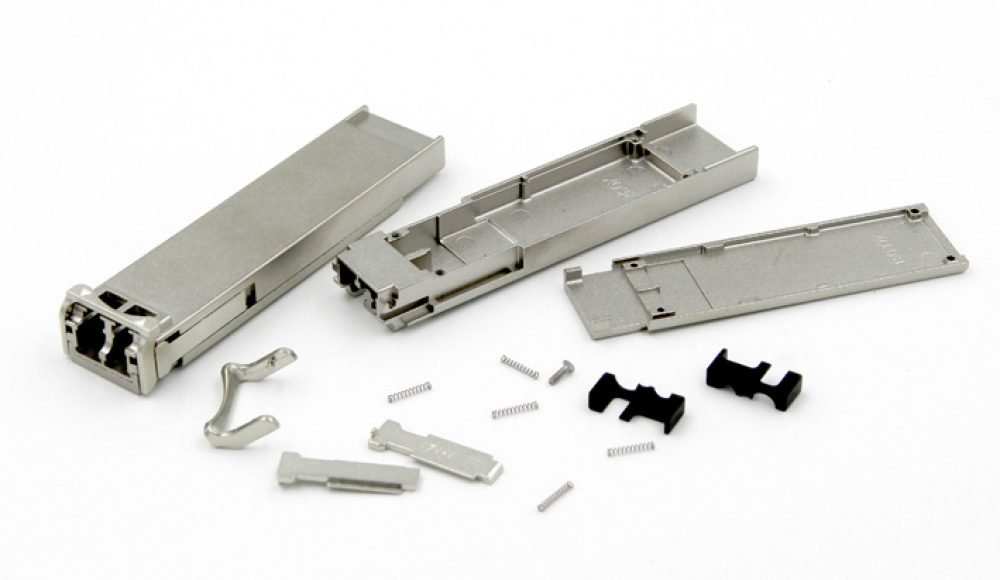

Hybrid housings combine the benefits of both metal and plastic. They typically incorporate metal parts for heat dissipation and EMI shielding while using plastic to minimize weight and production costs. This blend often results in a balanced housing option that addresses a wide spectrum of operational requirements.

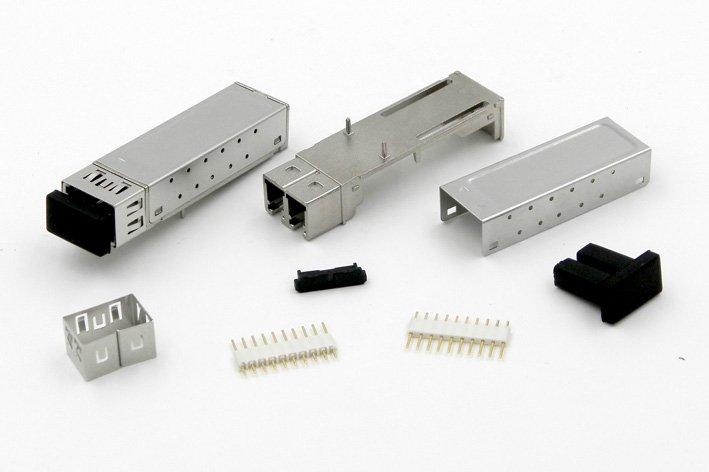

Various industry standards such as the Small Form-factor Pluggable (SFP), SFP+, Quad Small Form-factor Pluggable (QSFP), and QSFP+ dictate the specific requirements for optical transceiver housings. These standards ensure that the housings meet strict guidelines for size, durability, and compatibility. For instance, SFP and SFP+ housings are compact and suitable for high-density applications, while QSFP and QSFP+ can handle higher data rates suitable for data centers and enterprise networks.

Technological advancements have continuously enhanced the design of optical transceiver housings. Innovations in material science and manufacturing techniques have resulted in housings that are not only more efficient but also more cost-effective. These improvements are vital for supporting the growing demand for faster, more reliable network solutions.

Importance

In the realm of optical transceivers, the importance of high-quality housing cannot be overstated. A well-designed housing safeguards the internal components against physical damage, ensuring the longevity and consistent performance of the transceivers. Signal integrity is significantly influenced by the quality of the housing, as it provides the necessary shielding to minimize electromagnetic interference (EMI) and crosstalk from adjacent circuits, thereby maintaining the purity of data transmission.

The thermal performance of optical transceivers is another critical factor impacted by the housing. High-grade materials and meticulous design enable efficient heat dissipation, preventing the components from overheating and thus extending the device’s operational lifespan. Effective thermal management is essential, particularly in densely packed data centers where high temperatures can degrade performance and lead to failures.

Advantages

Furthermore, the physical protection offered by robust housing is indispensable for preventing contamination from dust and moisture. In harsh environments, transceivers are susceptible to such contaminants, which can compromise functionality. Quality enclosures include seals and barriers that keep detrimental elements at bay, ensuring reliability even under challenging conditions.

Besides protection, the design and build quality of optical transceiver housing have pragmatic implications for installation and maintenance. Precision-engineered housings facilitate easier installation through accurate alignment and secure fixture. This ease of installation translates to reduced downtime during network upgrades or repairs and optimizes the overall efficiency of network management. Regular maintenance also becomes less cumbersome when transceivers are housed in durable and accessible enclosures.

Conversely, utilizing low-quality housing can lead to myriad issues, including frequent maintenance requirements and unplanned network downtimes. Inferior housings may fail to provide adequate shielding and thermal management, leading to signal degradation and component failures. Dust and moisture ingress further exacerbate these problems, ultimately escalating maintenance costs and disrupting network operations. Therefore, investing in high-quality optical transceiver housing is a prudent decision for ensuring robust network performance and longevity.

We sincerely hope to cooperate with you to build our future together!