Introduction to Optical Transceivers and Their Casings

Optical transceiver casing is pivotal components in contemporary telecommunications and data communication systems. These devices facilitate the conversion of electrical signals into optical signals and vice versa, enabling high-speed data transmission over long distances. As the backbone of fiber optical communication, optical transceivers significantly enhance the efficiency and performance of network infrastructures.

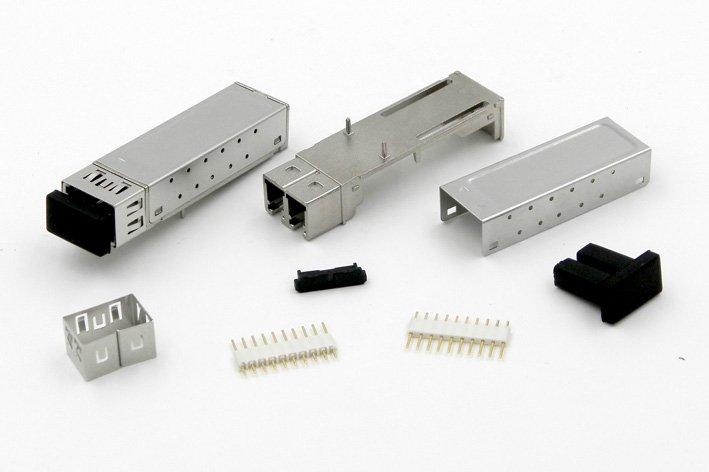

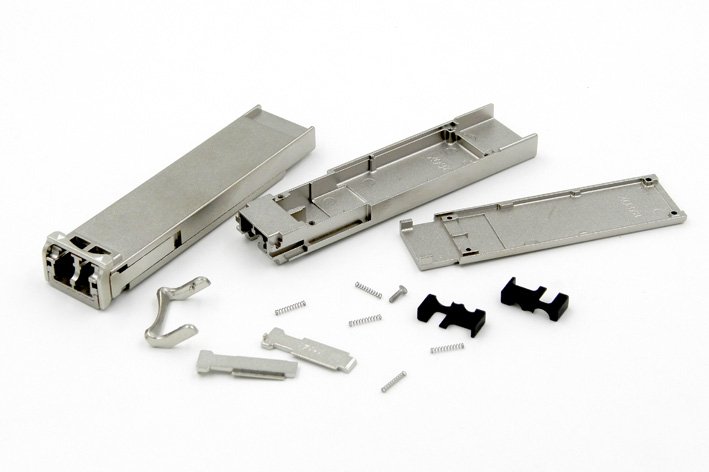

Primarily, the optical transceiver includes a transmitter that converts electrical signals into optical signals. And a receiver that converts optical signals back into electrical signals. This dual functionality is paramount in ensuring seamless data exchange across varying mediums. The wide array of optical transceivers available today includes several forms such as Small Form-factor Pluggable (SFP), Quad Small Form-factor Pluggable (QSFP), and C Form-factor Pluggable (CFP). Each type caters to distinct application requirements, from short-range data center links to long-haul telecommunications.

Types

SFP transceivers are commonly used in Ethernet switches, routers, and network interface cards. Effectively support speed changes from 1 Gbps to 10 Gbps. The QSFP module has higher density and data rate capabilities. It is crucial in data centers to provide speed capabilities of up to 100 Gbps. At the same time, the CFP transceiver specially designed for the Internet backbone and MAN has expanded its coverage to 400 Gbps, meeting the growing bandwidth demand.

Historically, optical transceiver casing have been constructed from metallic materials, given their robustness and thermal conductivity. However, the increasing adoption of plastic parts in these casings marks a significant shift in the industry. Plastic components offer notable advantages such as reduced weight, cost-effectiveness, and enhanced flexibility in manufacturing complex shapes. The emergence of high-performance plastics has mitigated earlier concerns regarding durability and heat dissipation, making them a viable alternative to traditional metallic counterparts.

Integrating plastic components into the optical transceiver housing represents a step forward. Consistent with the industry’s ongoing pursuit of innovation and efficiency. With the development of technology, it is expected that the materials and design of optical transceiver housings will further advance. Thus promoting the improvement of communication network functionality and sustainability.

Benefits of Using Plastic Parts in Optical Transceiver Casings

In the realm of optical transceiver casing, the utilization of plastic parts presents a multitude of compelling advantages. Firstly, plastic components significantly contribute to a reduction in overall weight compared to their metal counterparts. This lightweight characteristic simplifies handling and installation processes, making them more efficient and less labor-intensive. Whether in large-scale data centers or compact networking setups, this advantage is crucial for operational effectiveness.

Furthermore, plastic materials generally offer a cost-effective solution for manufacturers. The economical nature of plastics stems from both lower material costs and more streamlined manufacturing processes. Unlike metals, plastic can be molded into complex shapes and sizes through cost-efficient techniques such as injection molding, which can lead to lower production costs and faster turnaround times. This flexibility in design not only facilitates the creation of customized casings tailored to specific applications but also promotes innovative approaches to optical transceiver design.

Importance

Additionally, the thermal Additionally, the thermal and electrical insulation properties of plastic serve as vital protective elements for the delicate internal components of optical transceivers. Plastic components can effectively shield these sensitive parts from external electrical interferences and thermal fluctuations, thereby maintaining the integrity and functionality of the device under varying environmental conditions. This intrinsic characteristic is particularly beneficial in high-density environments where electronic interference could otherwise compromise performance.

Moreover, the flexibility afforded by plastic in terms of design cannot be understated. Plastics can be easily engineered to accommodate unique casing requirements, offering substantial versatility. This adaptability ensures that the optical transceiver casing can meet a wide range of specifications and operational demands, thus enhancing its application scope across diverse industries.

In summary, the benefits of employing plastic parts in optical transceiver casings are multifaceted. From reduced weight and cost-efficiency to enhanced protective features and design flexibility, plastic emerges as a superior material choice that supports both innovative design and reliable performance in optical transceiver manufacturing.

We sincerely hope to cooperate with you to build our future together!