Advantages of Injection for Optical Module Housing

Injection molding is a widely used manufacturing process for producing various components, including optical module housings. When it comes to optical module housings, injection molding offers several advantages that make it the preferred choice for many manufacturers.

1. Cost-Effective Production

Injection molding allows for high-volume production at a relatively low cost. The process involves injecting molten plastic into a mold cavity, which is then cooled and solidified to form the desired shape. This automated process enables manufacturers to produce optical module housings efficiently and at a faster rate compared to other manufacturing methods. The ability to produce large quantities at a lower cost makes injection molding an economical choice for optical module housing production.

2. Design Flexibility

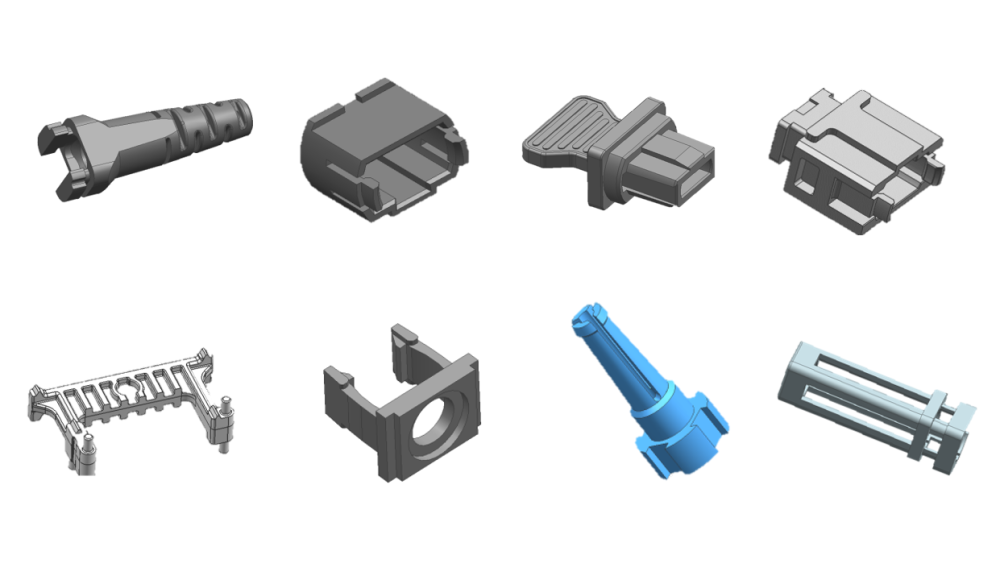

Injection molding provides designers with a high degree of flexibility when it comes to the design of optical module housings. The process allows for the creation of complex shapes, intricate details, and precise dimensions. Designers can incorporate features such as snap-fit connectors, mounting brackets, and internal structures to optimize the functionality and performance of the optical module housing. Manufacturers have the freedom to experiment with different design iterations and easily make modifications to meet specific requirements.

3. Excellent Material Properties

Optical module housings require materials with specific properties such as high strength, heat resistance, and dimensional stability. Injection molding allows for the use of a wide range of materials that possess these desired properties. Manufacturers can choose from various thermoplastics, including polycarbonate, ABS, and nylon, to meet the specific requirements of the optical module housing. The ability to select the appropriate material ensures that the housing can withstand harsh environmental conditions and provide long-term reliability.

In conclusion, injection molding offers numerous advantages for the production of optical module housings. Its cost-effectiveness, design flexibility, and ability to utilize materials with excellent properties make it an ideal choice for manufacturers in the optical industry.

Don’t mind to inquiry us pls. I’ll try my best to promote our future chatting.