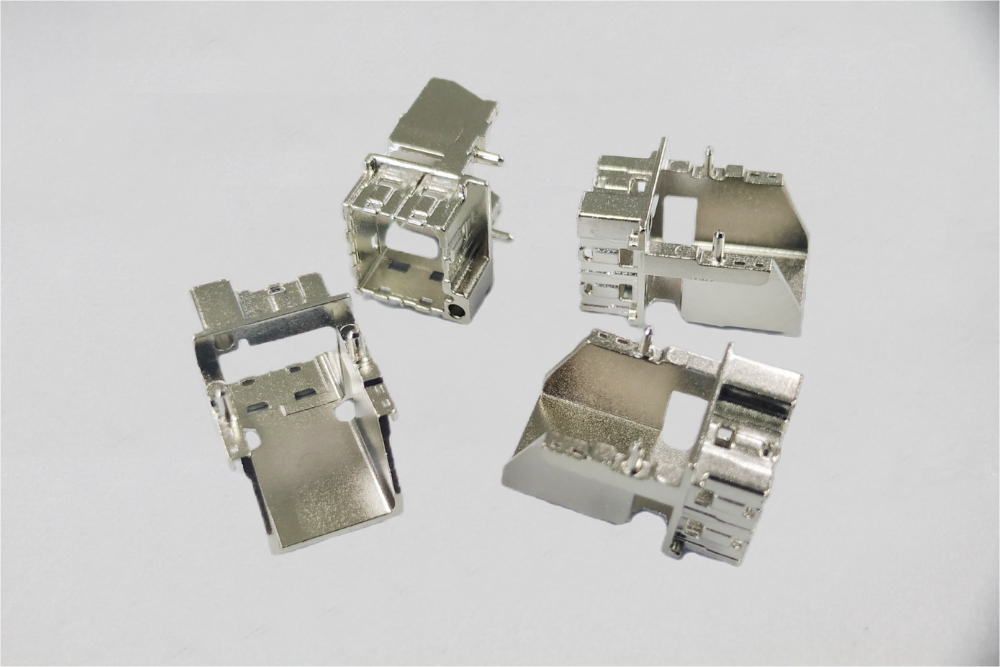

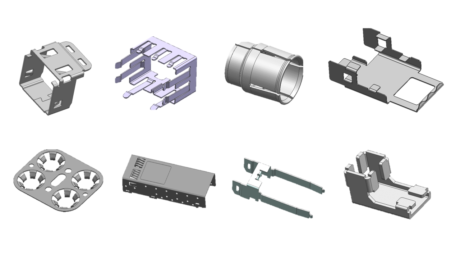

Die-Casting Auto Accessories are high-quality die cast components. Die casting is a precision casting method, it uses high pressure to melt metal and then press it into various shapes of metal molds. Produced using a range of materials including aluminum, zinc, copper, brass, and bronze alloys. Once a component using die casting technology, it can further refined through CNC machining. Surface treatment is usually carried out through processes such as shot peening, texture treatment, electroplating, and painting.

Die-Casting Auto Accessories

| Product Name | Die-Casting Auto Accessories |

| Main processes | Die-Casting |

| Design | Customized |

| Software | PRO/E, Auto CAD, Solid Works, Ug, CAD, CAM |

| Application Area | Motor Industries |

| Surface Treatment | Zinc, Nickel, Chrome plating, Hot Galvanized, Anodize and polishing, etc |

| Lead Time | Mold: 25-30days; Mass production: 15days; Sample Lead Time: 7days |

| Performance Testing | Salt spray test, Double 85 test, Hundred grid test, Aging test, etc |

| Packaging | Packaging method: Inner-Blister box/Plastic Bag; Outer -Standard Carton Box |

| Shipping | We can send your samples by FedEx/DHL/TNT/UPS. Pls contact us directly and we will use your preferred ways |

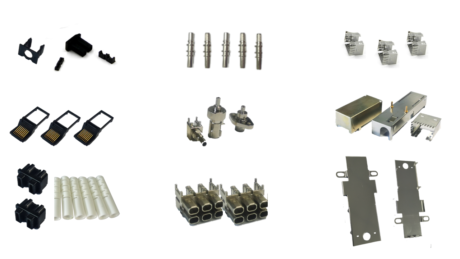

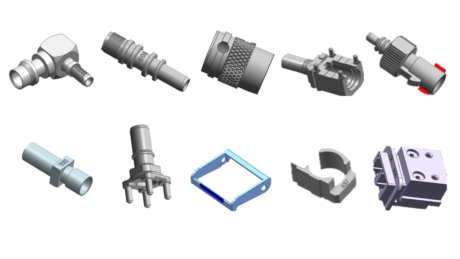

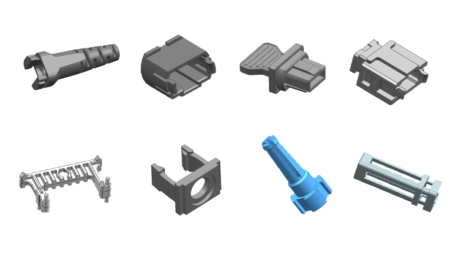

Recommend Products

Precision Die Castings Injection Parts Stamping Parts

Why Us

1.Our Die-Casting Auto Accessories from us are sure to have quality warranty, and they are double tested before shipping.

2.Our Die-Casting Auto Accessories can sent within 10-15 working days after payment arrives at us. In addition to batch processing, we will confirm delivery in advance.

3.Any import fees or charges are the buyer’s responsibility. But we can help you reduce and avoid import taxes by declaring prices low, declaring the contents as “electronic accessories” or other items and shipping in simple packaging.

4.Strong capacity to help customers develop new projects.

5.We will provide you with competitive price.

Contact Us

Want to know more information about Die-Casting Auto Accessories, don’t mind to inquiry us pls. I will do my best to introduce our products to you and answer your questions.

Tel:0768-85392772

Cell:+86-15080626495

Skype: live:lisa_14447

E-mail:zoey@ygsfp.com