Introduction to Precision Stamping

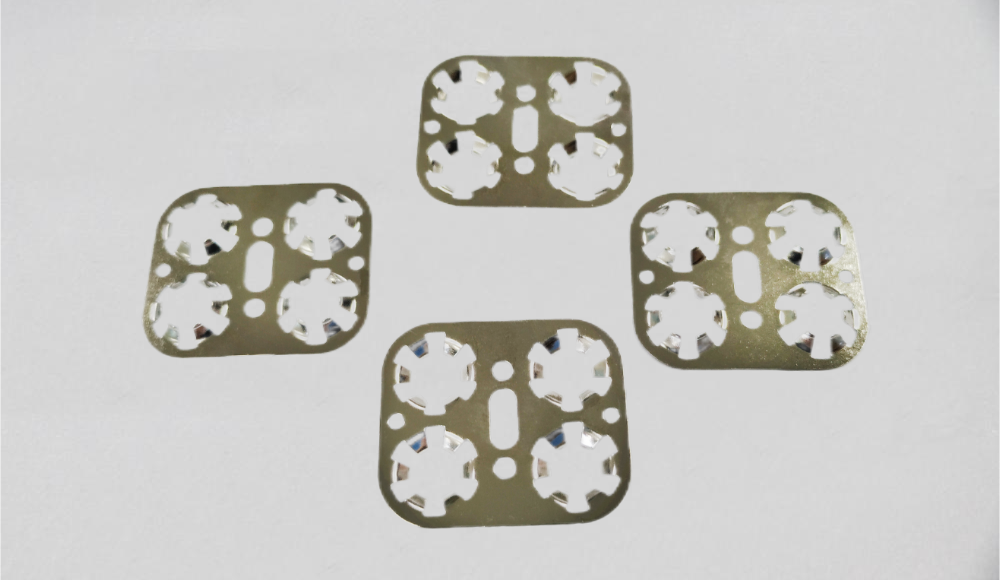

Precision stamping is a critical process in the manufacturing industry, offering high-quality and accurate production of metal components. This technique involves the use of sophisticated machinery to shape metal sheets into desired forms with exceptional precision.

Advantages of Stamping Parts

Using stamping parts offers several advantages. Firstly, they provide excellent consistency and precision, which is crucial for maintaining quality standards. Secondly, the stamping process is highly efficient, allowing for large-scale production while keeping costs low. Lastly, the versatility of stamping parts means they can be customized to meet specific requirements.

One of the primary benefits of precision stamping is its ability to produce intricate designs with tight tolerances. This ensures that each component meets the exact specifications required for advanced applications. Additionally, this process is highly efficient, reducing material waste and production time.

1. Stamping is a processing method with high production efficiency and low material consumption. Stamping technology is suitable for the production of large quantities of parts and products, facilitating mechanization and automation, and has high production efficiency. At the same time, stamping production not only strives to achieve low waste and zero waste production, but also can fully utilize even if there are corner residues in some cases.

2. The operation process is convenient and does not require the operator to have a high level of skills.

3. Stamped parts generally do not require further mechanical processing and have high dimensional accuracy.

4. Stamping parts have good interchangeability. Stamping processing has good stability, and the same batch of stamped parts can be exchanged and used without affecting assembly and product performance.

5. Due to the use of sheet metal as the material for stamping parts, its surface quality is good, providing convenient conditions for subsequent surface treatment processes such as electroplating and painting.

6. Stamping processing can obtain parts with high strength, high rigidity, and light weight.

7. The cost of mass-produced stamping parts using molds is low.

8. Stamping can produce complex shaped parts that are difficult to process using other metal processing methods.

Applications of Precision Stamping

Precision stamping is widely used in various industries, including automotive, aerospace, electronics, and medical devices. Its versatility and accuracy make it an ideal choice for producing high-quality parts that are essential for the performance and reliability of complex systems.

We sincerely hope to cooperate with you to build our future together!