Specialized Production

Customized Service

ABOUT YOUGE

We offer our customers with product development、production molds、precision die casting、precision machining parts、precision injection molding、precision stamping. From Design to Prototyping to Production, we are always ready to turn your ideas into reality and provide advanced manufacturing solutions suitable for your products.

Rapid Prototyping

We are your reliable R&D partner. From a CAD design to a physical prototype in your hands, and finally to your team, it is faster than ever. We have developed the latest rapid prototyping technology to meet your design challenges, and will work with you to verify and improve your product ideas, functional testing, and engineering verification. Our rapid prototyping services include CNC prototyping, 3D printing, vacuum casting, rapid tooling, sheet metal prototyping, and prototype finishing.

Rapid ManufactuRapid Manufacturing

We are also your best manufacturing partner. We offer a range of solutions to help you scale from effective prototypes to production parts. Our rich manufacturing experience and ability to integrate resources enable us to handle any project’s needs and ensure your parts always meet the highest quality standards. Custom rapid manufacturing services include CNC machining, plastic injection molding, metal casting, sheet metal fabrication, and parts finishinring.

OUR CAPABILITIES

PROTOTYPING

Youge helps companies and entrepreneurs around the world manufacture prototypes for their businesses. There is no minimum order quantity, and your business can benefit from our design and process expertise as well as our ability to quickly scale up production.

CNC MACHINING

Youge provides high-quality, tight toleranced components machined from bar stock. Also finishes as-cast and as-forged components. We can provide a range of materials, from soft aluminum and brass to hard titanium and cobalt-chrome alloys.

DIE CASTING

Youge provides high-quality die-cast components produced using a range of materials including aluminum, zinc, copper, brass, and bronze alloys. Once a component has been die-cast, it can be further refined with CNC machining. Surface finishes are commonly applied through processes like shot-blasting, texturing, plating, and painting.

METAL STAMPING

Youge produces custom sheet metal stampings in a wide range of custom materials. Some of the materials include cold-rolled steel (CRS), hot-rolled steel, stainless steel, galvanized, brass, aluminum, and beryllium copper among others. We offer complete secondary operations including powder coating, painting, anodizing, silk screening, and pad printing. Assembly services are also available.

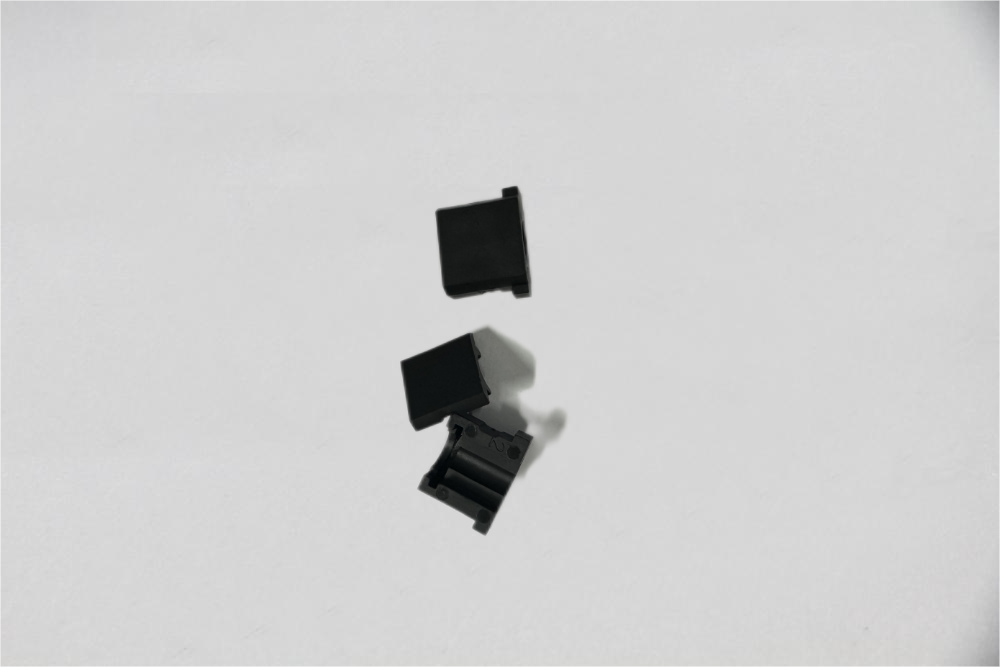

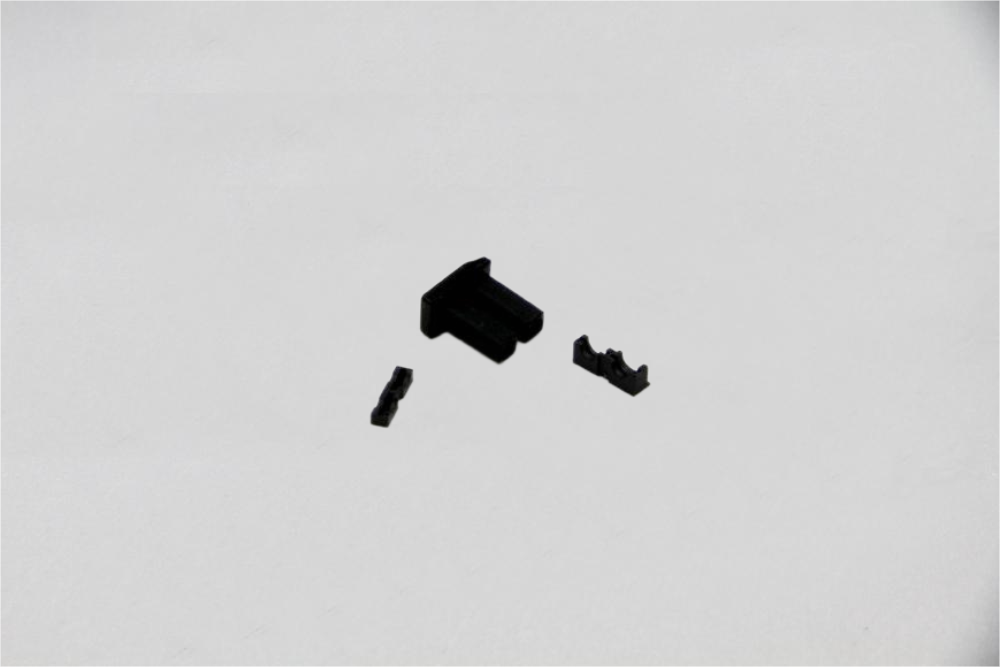

PLASTIC INJECTION

Injection molding can produce parts in a wide range of sizes and complexity. Small features, intricate geometries, and thin walls can be captured with ease using the injection molding process. Injection-molded components can be post-processed via various surface finishing options such as painting and texturing.

ASSEMBLIES

With large flexible layout factories,Youge is able to set up dedicated assembly lines as per the volume requirements for a wide variety of electro-mechanical products and assemblies.

FACTORY SCENCE